close

Choose Your Site

Global

Social Media

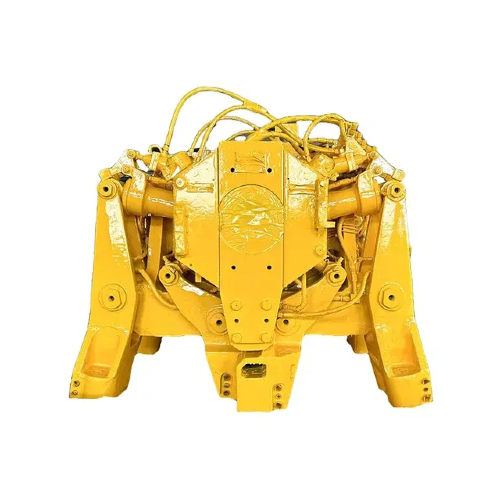

The Stabilizer (also known as a Track Stabilizer) is a vital piece of railway maintenance equipment designed to reinforce ballast bed stability and reduce track settlement. Unlike tampers (which focus on compacting ballast under sleepers), the Stabilizer works by applying uniform downward pressure and low-frequency vibration to the entire ballast layer—locking particles into a permanent, dense configuration. This process eliminates "false compaction" (temporary ballast tightness that loosens over time) and extends the interval between maintenance cycles by 50%.

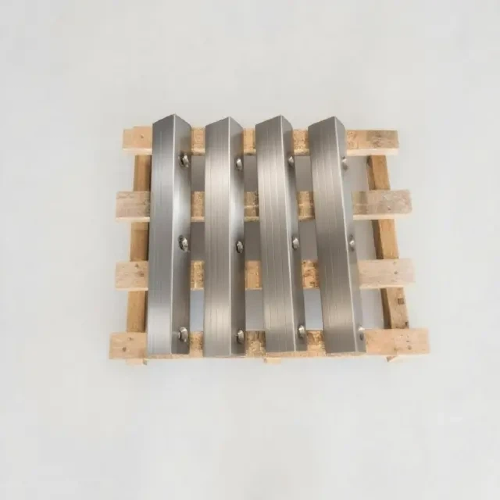

The Tamping Pick ND-6 is a specialized tool for railway and subway line maintenance, designed to deliver precise and efficient tamping of track ballast.

The Internal Combustion Turnout Grinding Machine NCM-4II is an upgraded version of the NCM-4.9, specifically optimized for heavy-duty railway scenarios like mining railways and Heavy-duty cargo lines.

What is the Machine that Cleans Railroad Tracks?Exploring the Role of Ballast Cleaning Machines in Railway MaintenanceBallast cleaning is a crucial process for ensuring the stability, safety, and longevity of railway tracks. Ballast, the layer of crushed stones or gravel placed beneath railway track

What is Ballast Cleaning?An In-Depth Guide to Ballast Cleaning and Its Importance in Railway MaintenanceBallast cleaning is a critical process in the maintenance of railway infrastructure, ensuring that the tracks remain stable, safe, and functional. Ballast serves as the foundation for railway trac

Best Material for Half Tamping Pick ProductionHalf tamping picks play a pivotal role in railway maintenance by compacting ballast, ensuring track stability, and enhancing safety. As essential tools for track engineers, choosing the right material for production is critical for durability, performanc