Rail Grinder for Smoother, Safer, and Quieter Train Operations

Upgrade rail maintenance with Kuntie Rail Grinder offering precise defect removal, smoother rail profiles, and extended service life across all railway systems.

The Rail Grinding Solution Operators Need for Reliability, Efficiency, and Lower Maintenance Costs

Railway tracks endure heavy loads and frequent operations, causing surface defects, noise, cracks, and profile distortion that impact safety and increase maintenance pressure. Rail grinding offers a proactive solution by removing damaged layers and restoring the rail’s geometry before problems worsen. It improves wheel-rail interaction, reduces noise, extends rail life, and enhances overall reliability. For operators, effective grinding cuts long-term costs, minimizes downtime, and ensures smoother, safer, and more efficient performance across mainlines, metros, and turnout zones. Kuntie offers a full Grinding Car Series, including medium-sized intelligent rail-finishing vehicles, four-head grinding robots, and dual-headed turnout grinding machines-able to grind mainlines, metros, tight-curve tracks and turnouts, even in restricted or hard-to-reach areas.

Product Center

How Kuntie Rail Grinders Solve Key Track Challenges

Kuntie-leading Chinese manufacturer driving innovation in road and rail maintenance machinery.

Fast Defect Removal in Tight Maintenance Windows

Kuntie’s intelligent grinding vehicles and robots quickly eliminate cracks, corrugation, and surface damage within limited maintenance windows, restoring rail geometry, improving safety, and supporting reliable operations on high-speed, metro, and heavy-traffic lines.

Precision Grinding for Turnouts and Hard-to-Reach Areas

Our four-head and dual-headed turnout grinders access curves, switches, and restricted zones where large grinding trains cannot operate—delivering complete rail maintenance, reducing lifecycle costs, and preventing premature rail replacement.

Kuntie’s Three Core Rail Grinding Products

Engineered for modern rail networks, Kuntie grinders restore rail geometry, eliminate surface damage, and optimize long-term performance in challenging maintenance conditions.

Medium-Sized Intelligent Rail Grinding Vehicle

Kuntie’s mid-sized grinder uses automatic lift and multi-head grinding to enter/exit tracks quickly — ideal for short-distance maintenance windows and precision rail profile restoration on busy mainlines.

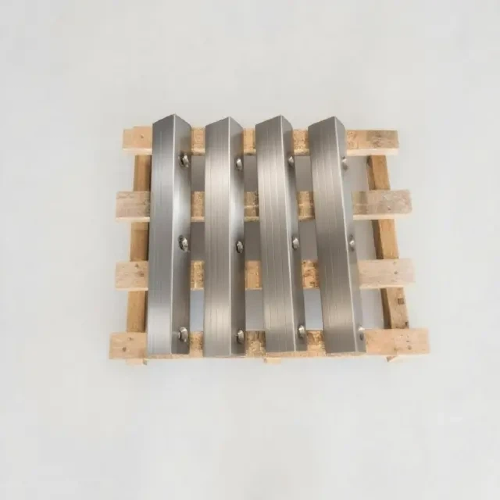

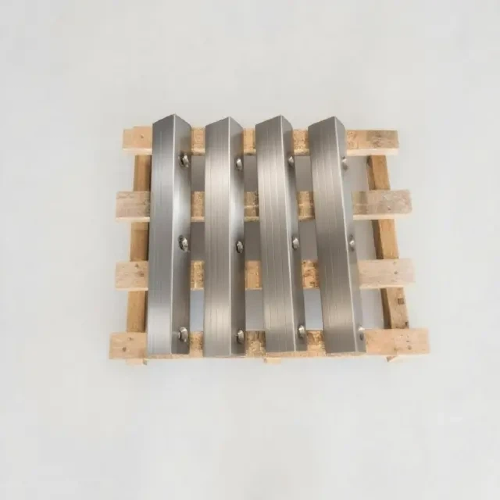

Four-Head Railway Grinding Robot

This compact, lightweight grinder tackles “restricted areas” and tight-curve/high-speed rail switches where large machines can’t reach — solving switch-section maintenance bottlenecks efficiently.

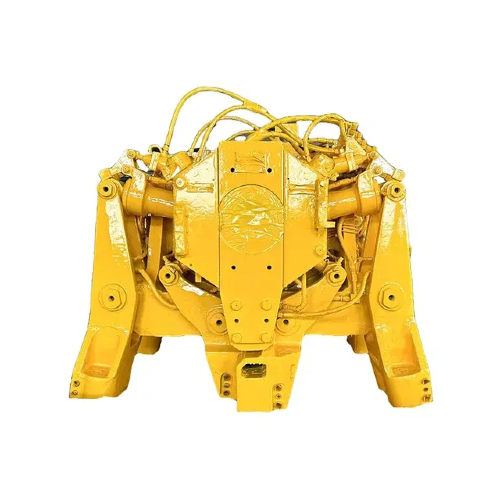

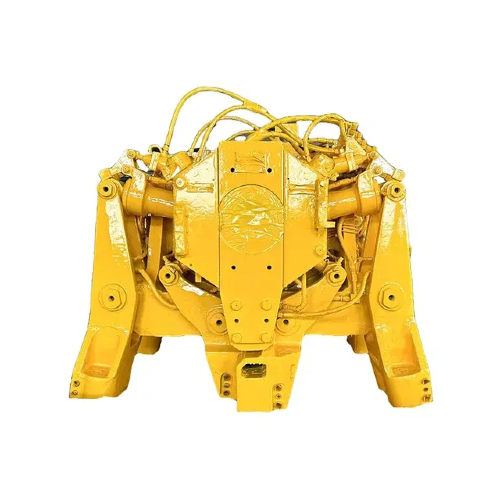

Double-Ended Turnout Grinding Robot

Equipped with dual grinding heads and real-time profile monitoring, it precisely grinds both switch and fork parts of turnouts, eliminating blind-spot wear and ensuring safety and smooth train operations.

How Kuntie Delivers Full-Service Support in Four Steps

Customized Solutions

We assess your railway type, maintenance frequency and budget — then tailor one-on-one equipment configuration to match your specific line conditions.

Spare Parts Supply

Provide full modular original parts supply for grinders and tampers; support emergency delivery and batch orders — ensuring compatibility and lowering upgrade cost by ~25%.

Fast Replacement & Maintenance Service

With 12 regional service centers across the country, we offer rapid part replacement (within 72 hours) and full maintenance services to keep your equipment operating smoothly.

Warranty & After-Sales Support

We offer 365-day full-cycle warranty, lifetime cost-price spare parts, 7×12 h remote technical support, plus on-site or online training to help you operate and maintain the equipment confidently.

Download

- Name

- Summary

- Category

- Update

- Size

- Downloads

- Thumbnail

- Download

- Copy Link

- Kuntie Railway Brochure.pdf

- Uncategorized

- 2025-12-12

- 164.16MB

- 3

-

- Download

- Copy Link

FAQs

Related Blogs

-

What is the Machine that Cleans Railroad Tracks?Exploring the Role of Ballast Cleaning Machines in Railway MaintenanceBallast cleaning is a crucial process for ensuring the stability, safety, and longevity of railway tracks. Ballast, the layer of crushed stones or gravel placed beneath railway trackBlogs

What is the Machine that Cleans Railroad Tracks?Exploring the Role of Ballast Cleaning Machines in Railway MaintenanceBallast cleaning is a crucial process for ensuring the stability, safety, and longevity of railway tracks. Ballast, the layer of crushed stones or gravel placed beneath railway trackBlogs -

What is Ballast Cleaning?An In-Depth Guide to Ballast Cleaning and Its Importance in Railway MaintenanceBallast cleaning is a critical process in the maintenance of railway infrastructure, ensuring that the tracks remain stable, safe, and functional. Ballast serves as the foundation for railway tracBlogs

What is Ballast Cleaning?An In-Depth Guide to Ballast Cleaning and Its Importance in Railway MaintenanceBallast cleaning is a critical process in the maintenance of railway infrastructure, ensuring that the tracks remain stable, safe, and functional. Ballast serves as the foundation for railway tracBlogs -

Best Material for Half Tamping Pick ProductionHalf tamping picks play a pivotal role in railway maintenance by compacting ballast, ensuring track stability, and enhancing safety. As essential tools for track engineers, choosing the right material for production is critical for durability, performancBlogs

Best Material for Half Tamping Pick ProductionHalf tamping picks play a pivotal role in railway maintenance by compacting ballast, ensuring track stability, and enhancing safety. As essential tools for track engineers, choosing the right material for production is critical for durability, performancBlogs -

How to Choose the Right Full Tamping Pick: A Comprehensive GuideA full tamping pick is an essential tool in the railway industry, primarily used for track maintenance. The effectiveness of this tool directly influences the quality and safety of the railway system. Track maintenance workers rely on tBlogs

How to Choose the Right Full Tamping Pick: A Comprehensive GuideA full tamping pick is an essential tool in the railway industry, primarily used for track maintenance. The effectiveness of this tool directly influences the quality and safety of the railway system. Track maintenance workers rely on tBlogs

Keep In Touch With Us

If you have any questions or requirements, please feel free to contact our customer service team. Our professional team will provide you with detailed product information, answer your questions, and tailor the best solution to meet your needs.

Mob:+8618131595437

E-mail:kuntietangshan@gmail.com